A safety harness is an essential component of personal protective equipment (PPE) for individuals working at heights. Proper fit and usage can significantly reduce the risk of severe injury or fatality in the event of a fall.

In Canada, federal and provincial laws govern the use of safety harnesses to ensure worker safety. This article will cover the key components of a safety harness, the relevant legislation, and how to use it correctly on a construction site.

Learning how to use a safety harness properly can greatly reduce fall risks. It ensures your safety and shows your dedication to workplace safety. This is essential for any responsible and skilled construction professional.

Understanding Safety Harness Components and Requirements

To ensure proper use of fall arrest systems on construction sites, it’s crucial to understand the essential components of a safety harness and the current regulations. This knowledge equips construction workers with the necessary skills to stay safe and compliant while on the job.

Essential Parts of a Fall Protection System

A comprehensive fall protection system consists of three main elements: the safety harness, the connecting device (such as a lanyard or self-retracting lifeline), and the anchor point. The harness distributes the force of a fall across the worker’s body, the connecting device limits the distance of a potential fall, and the anchor point provides a secure attachment point.

Types of Safety Harnesses for Construction Work

There are several types of safety harnesses designed for construction work, each suited for different job tasks and environments. Full-body harnesses distribute the impact of a fall across the worker’s shoulders, chest, and thighs, making them a popular choice. Positioning harnesses allow workers to lean back and be supported while performing tasks. Specialty harnesses, such as those with retrieval capabilities, may be necessary for specific construction activities.

Selecting the appropriate safety harness and ensuring its proper use are crucial steps in protecting construction workers from the risks of falls. By understanding the components of a fall protection system and staying up-to-date with regulations, construction companies can provide a safer working environment and promote a culture of workplace safety.

Correctly Using a Safety Harness on a Construction Site

Using a safety harness on a construction site is vital for protecting workers from falls. The process of harness fitting and adjustment is key to ensure the harness supports and secures properly. It’s also crucial to understand and prevent suspension trauma for safe harness use.

How to Properly Fit a Safety Harness

Properly fitting a safety harness is critical to its effectiveness. Follow these steps to ensure maximum safety and comfort:

1. Inspect the Harness

- Visual Check: Look for frayed webbing, broken stitching, or damaged buckles.

- Functionality Test: Ensure all buckles and adjusters work smoothly.

2. Identify the Components

- Understand the parts of the harness, including shoulder straps, leg straps, chest straps, and D-ring (attachment point).

3. Put On the Harness

- Hold the D-ring and shake the harness to untangle straps.

- Slip your arms through the shoulder straps as if putting on a vest.

4. Adjust the Leg Straps

- Buckle the leg straps securely around your thighs.

- Tighten until they are snug but not uncomfortable—ensure you can fit two fingers between the strap and your leg.

5. Adjust the Chest Strap

- Secure the chest strap across the mid-chest area.

- Tighten it until it sits snugly without restricting breathing – ensure you can fit your fist between the strap and your chest.

6. Check the D-ring Position

- Ensure the D-ring is positioned between your shoulder blades, at the center of your back.

7. Perform a Final Check

- Ensure there are no loose or twisted straps.

- Verify that all buckles are secure and properly fastened.

- Conduct a movement test to confirm the harness remains snug and comfortable.

Suspension trauma, a condition that can occur when a worker is suspended in a safety harness, is a serious concern. To prevent this, it’s important to have a plan for a prompt rescue in case of a fall. This could include having a co-worker nearby to assist or having a pre-determined method for self-rescue.

“Proper harness fitting and adjustment is crucial to ensure the safety and security of workers on a construction site. Failing to address this can lead to devastating consequences, including suspension trauma, which can be life-threatening.”

By following these steps and understanding the importance of suspension trauma prevention, workers can ensure they are using their safety harnesses effectively. This reduces the risk of falls on a construction site.

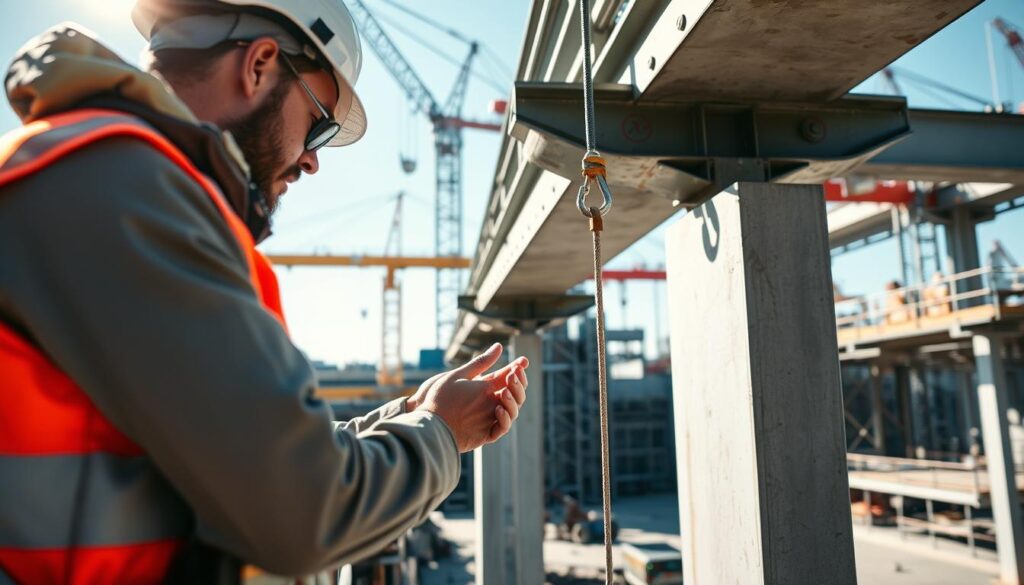

Selecting and Inspecting Anchor Points

Choosing the right anchor points for fall protection equipment is vital on construction sites. It involves identifying suitable locations, understanding weight and force needs, and conducting regular inspections. These steps are key to ensuring your safety harness system works effectively and safely.

Identifying Suitable Anchor Locations

Look for strong, stable structures that can handle the force of a fall when picking anchor points. Beams, columns, or other fixed structures that can support the required weight are good choices. Avoid damaged, deteriorated, or unstable points.

Selecting the Right Anchor Point

1. Strength Requirements

Anchor points in Canada must meet the following minimum strength standards:

- Fall Arrest Systems: Anchor points must withstand a force of at least 22.2 kN (5,000 lbs).

- Travel Restraint Systems: Anchor points must withstand a force of at least 3.5 kN (800 lbs).

2. Location

- Choose a location directly above the worker to minimize the swing fall effect.

- Ensure the anchor point reduces potential fall distance.

3. Compatibility

- The anchor point must be compatible with the fall protection equipment being used.

- Avoid using makeshift anchor points like pipes, guardrails, or other non-rated structures.

4. Inspection

- Regularly inspect anchor points for signs of wear, corrosion, or damage.

- Certified personnel should perform inspections in accordance with the manufacturer’s instructions and regulatory requirements.

Regular Inspection Protocols

Regularly checking your anchor points is essential for a safe fall protection system. Set up a routine inspection schedule to look for wear, damage, or deterioration. Keep records of your inspections and fix any problems right away to keep your workers safe.

| Anchor Point Inspection Checklist | Frequency |

| Visual Inspection | Daily |

| Detailed Inspection | Weekly |

| Comprehensive Inspection | Monthly |

By carefully choosing and inspecting your anchor points, you can ensure your fall protection equipment is safe and reliable. This protects your workers from the dangers of working at height on construction sites.

Maintaining and Storing Your Safety Harness

Keeping your safety harness in good condition is crucial for its reliability and longevity. It is vital to maintain your fall protection gear. Regular checks, proper cleaning, and correct storage extend your harness’s life and ensure compliance.

Ensure that you meticulously inspect your harness before each use, looking for wear, damage, or degradation. Examine the webbing, buckles, and connection points for fraying, cuts, or cracks. The D-ring’s condition and the harness’s fit are also key. Clean it with mild soap and water, avoiding harsh chemicals that could harm the material.

Proper storage is equally important. A harness should be kept in a cool, dry spot, away from sunlight and extreme temperatures. If it is possible, it should be stored in a dedicated bag or container to shield it from dust, moisture, and other environmental factors. These simple steps will ensure your safety harness is ready to protect you when needed.

Conclusion

A properly fitted safety harness, coupled with adherence to relevant legislation, is crucial for protecting workers at heights. Employers and workers in Canada must understand their responsibilities under federal and provincial regulations to maintain a safe working environment.

By following the steps outlined above and staying compliant with the law, you can minimize risks and ensure the well-being of everyone on-site.