As a safety-conscious professional, I grasp the vital role of fall protection equipment in safeguarding workers across diverse sectors. In today’s fast-paced environment, where workplace dangers are omnipresent, prioritizing employee safety is paramount. I’m eager to share insights on fall protection equipment basics and its role in maintaining your team’s safety at work.

In this detailed poat, we’ll explore legislative mandates and industry standards for fall protection. We’ll also look at common workplace hazards that demand the use of such equipment. Additionally, we’ll discuss the financial and human toll of fall-related incidents. With this knowledge, you’ll be prepared to make informed choices and implement effective fall protection strategies for your team.

Understanding the Critical Role of Fall Protection in Workplace Safety

Worker safety is a top priority in every industry. Effective fall protection measures are essential. This includes safety harnesses, fall arrest systems, and following legislative and industry standards.

Legislative Requirements and Industry Standards

The legislation sets strict rules for fall protection. These standards cover the selection, installation, and upkeep of safety gear. Following legislative guidelines is not just a legal requirement; it’s vital for protecting workers from falls.

Common Workplace Fall Hazards

- Working at heights, such as on roofs, scaffolding, or ladders

- Elevated platforms or mezzanines

- Unprotected edges or openings

- Slippery or uneven surfaces

- Unstable or poorly maintained equipment

Cost of Fall-Related Incidents

Fall-related incidents come with high financial and human costs. legislative reports that falls are the leading cause of death in construction, with 366 worker fatalities in 2020.

These incidents lead to huge medical bills, lost productivity, and legal costs for employers. Investing in safety harnesses and fall arrest systems is crucial for both moral and business reasons.

| Cost Category | Average Cost |

| Medical Expenses | $50,000 – $100,000 |

| Lost Productivity | $27,000 – $70,000 |

| Legal Liabilities | $100,000 – $1,000,000 |

“Investing in reliable fall protection equipment is not only a moral obligation but also a sound business decision that can help mitigate the devastating costs of workplace falls.”

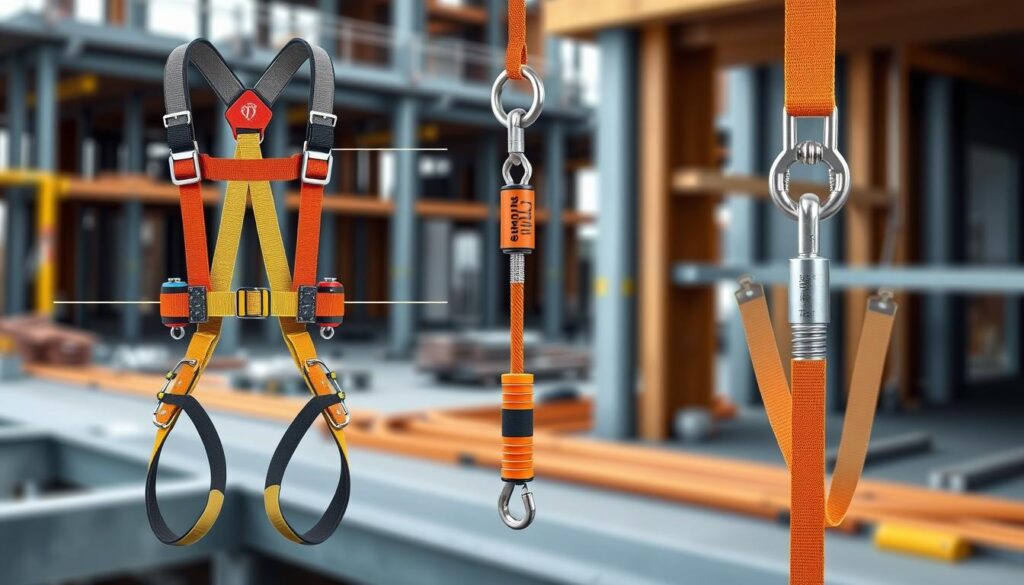

Essential Components of Personal Fall Arrest Systems

Protecting workers from falls is vital to workplace safety. At the core of this protection are personal fall arrest systems. These systems consist of several key components that work together seamlessly. Let’s delve into these critical elements.

Full-Body Harnesses

The cornerstone of a personal fall arrest system is the full-body harness. These harnesses spread the force of a fall across the worker’s shoulders, chest, and legs. This minimizes injury risk. They are available in various styles and sizes to fit different body types and job needs.

Lanyards and Connectors

Lanyards, connecting the harness to the anchorage point, are crucial. Made from durable materials like nylon or polyester, they absorb shock during a fall. Connectors, such as carabiners and snap hooks, are also vital. They securely link the lanyard to both the harness and the anchorage.

Anchorage Points

The last piece is the anchorage point, a stable structure that can handle fall forces. These anchor points, fixed or mobile, are the worker’s secure attachment point. They ensure a safe and reliable connection.

When full-body harnesses, lanyards, connectors, and anchorage points are chosen and used correctly, they form a robust personal fall arrest system. This system effectively safeguards workers from the dangers of falls.

“Investing in quality fall protection equipment is not just a wise decision, but a moral obligation to safeguard the wellbeing of our workforce.”

Fall Protection Equipment 101: What Every Worker Needs

Fall protection equipment is vital in workplace safety, protecting workers from falls. It’s a key part of any safety plan. Knowing the types of equipment and when to use them is crucial. Let’s explore the basics of fall protection and what to consider.

Basic Equipment Categories

The main fall protection equipment categories are:

- Fall arrest systems, such as full-body harnesses, lanyards, and self-retracting lifelines

- Guardrail systems, which provide a physical barrier to prevent falls

- Safety net systems, designed to catch workers in the event of a fall

When to Use Different Types of Protection

Choosing the right fall protection equipment depends on the work environment and fall hazards. For example, a full-body harness with a lanyard or self-retracting lifeline is best for areas with unprotected edges. Guardrails are better for low-level surfaces, while safety nets offer extra protection in high-risk areas.

Equipment Weight and Capacity Ratings

When picking fall protection equipment, weight and capacity ratings are key. These ensure the equipment can handle the worker and any tools or materials. Going over the weight limit can make the equipment ineffective, leading to serious incidents. Always check the manufacturer’s guidelines and choose equipment that fits the work tasks and worker needs.

| Fall Protection Equipment Type | Typical Weight Capacity | Typical Height Capacity |

| Full-Body Harness | 310 lbs (140 kg) | 6 ft (1.8 m) |

| Lanyard | 310 lbs (140 kg) | 6 ft (1.8 m) |

| Self-Retracting Lifeline | 310 lbs (140 kg) | 50 ft (15 m) |

| Guardrails | N/A | 42 in (107 cm) |

| Safety Nets | N/A | 6-10 ft (1.8-3 m) |

Understanding fall protection equipment categories, when to use them, and their weight and capacity ratings is essential. This knowledge helps workers stay safe on the job site.

Proper Installation and Inspection of Anchorage Points

In the realm of fall protection, anchorage points are vital for worker safety. Their proper installation and regular inspections are key to a robust fall protection system. The intricacies of anchorage points cannot be overlooked.

Choosing the right anchorage points is the first step. They must be able to handle the forces of a fall. Assess the work environment thoroughly, considering structural integrity, weight capacity, and accessibility. It’s crucial to follow the manufacturer’s installation guidelines to ensure the effectiveness of your equipment.

Regular safety inspections of anchorage points are also essential. I ensure each anchor point is inspected for wear, damage, or deterioration. This proactive approach helps catch issues early, maintaining the reliability of your systems and protecting your workers.